In today’s fast-changing industrial world, sustainable manufacturing is no longer a choice—it’s a necessity. The emergence of RepMold marks a major shift toward eco-friendly materials, waste reduction, and resource efficiency. This innovative approach empowers manufacturers to embrace recycling and reusing strategies while significantly lowering their environmental impact. As businesses strive to meet the expectations of eco-conscious consumers, RepMold introduces a method that seamlessly combines performance with responsibility.

By incorporating reusability and a closed production loop, RepMold reduces dependence on metals, plastics, and other energy-intensive raw materials. It helps industries adapt to new regulatory demands and climate goals by minimizing greenhouse gas emissions and promoting clean production. For both businesses and consumers, this breakthrough signals a promising new era of sustainable manufacturing.

Throughout this article, we’ll explore how RepMold works, its environmental advantages, manufacturing benefits, the challenges it faces, the role of regulations, improvements in quality, applications across industries, cost-performance gains, and what the future holds for this transformative system.

What Is RepMold? The Answer

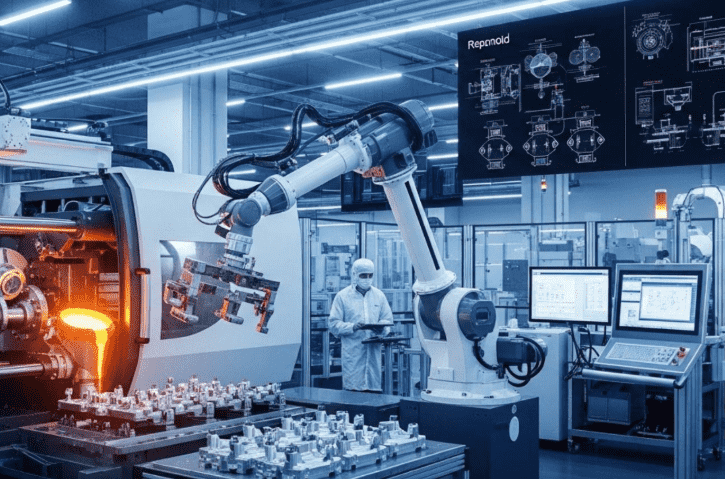

The RepMold system brings together the best of replication and molding techniques to produce high-quality components efficiently and sustainably. The term combines “Rep” for replication and “Mold” for shaping—capturing its dual focus on precision and repeatability. It allows manufacturers to reuse materials, molds, and design models to create parts that align with the principles of the circular economy.

This process starts with digital design—often through advanced CAD modeling—and continues through mold creation using composite materials or reinforced polymers. Once the master mold is formed, it can be reused to produce multiple components without generating excessive waste. This method contrasts with conventional manufacturing that depends on large quantities of virgin raw materials and lengthy production cycles.

The RepMold technique isn’t just a technical innovation; it’s a strategic shift toward sustainability. It encourages shorter production runs, customization, and reusability, all while maintaining high precision. For modern manufacturers, RepMold represents the bridge between efficiency and environmental responsibility.

The Impact of Sustainable Manufacturing on the Environment

Traditional manufacturing has long contributed to greenhouse gases, air pollution, and resource depletion through extraction of metals, plastics, and other non-renewable materials. The result is habitat destruction, biodiversity loss, and chemical runoff that harms water systems. Sustainable manufacturing aims to reverse this trend through waste reduction and eco-friendly materials that minimize harm to the planet.

By prioritizing recycling, reusing, and smarter production processes, companies can drastically reduce their carbon footprint. The circular approach transforms waste into new raw materials, creating a loop of continuous value. Manufacturers implementing such systems are helping to achieve global goals for climate change mitigation and environmental preservation.

The impact goes beyond factories. Businesses, consumers, and industry sectors benefit from cleaner air, reduced water contamination, and healthier communities. Companies adopting these methods earn the trust of eco-conscious buyers, strengthen brand reputation, and future-proof their operations against tightening environmental regulations.

Advantages of RepMold in Manufacturing Processes

RepMold offers a host of advantages for modern manufacturing. It drastically cuts production costs by reducing reliance on virgin raw materials and improving material efficiency. The circular system minimizes waste, lowers energy consumption, and enhances operational flexibility—making it easier for companies to respond quickly to market changes.

Another standout feature is precision. Through digital modeling and advanced technology, RepMold ensures consistent quality and exactness across every batch. Manufacturers benefit from reliable quality control and a smoother production cycle, which strengthens their competitiveness.

Finally, there’s the brand benefit. Adopting RepMold signals commitment to sustainability and innovation, attracting eco-conscious consumers and satisfying government regulations that favor renewable energy and low-emission production. For industries seeking an edge, RepMold combines practicality with environmental responsibility.

Challenges of RepMold

Despite its promise, RepMold faces several real-world challenges. The first is initial investment—transitioning to new systems often requires advanced equipment, staff training, and infrastructure upgrades. While these costs can be recouped through long-term savings, they remain a hurdle for small and mid-sized manufacturers.

Scalability is another concern. Although the process excels in short-to-medium production runs, it may need further refinement for high-volume operations. Finding the balance between efficiency, quality control, and speed requires ongoing research and development.

Material durability also presents a challenge. Selecting the right eco-friendly materials, managing mold wear, and ensuring consistent performance across batches demands continuous monitoring. In addition, consumer education plays a role—people must learn to appreciate products made with sustainable methods to drive widespread adoption.

The Role of Regulations in Promoting Sustainable Manufacturing

Regulations have a powerful influence on how manufacturing evolves. Governments and international bodies are now creating frameworks that encourage eco-friendly materials, recycling, and renewable energy use. Subsidies and incentives for sustainable innovation make it easier for manufacturers to adopt systems like RepMold.

Environmental standards are also becoming more rigorous, with penalties for high emissions, waste generation, or energy-intensive production methods. By enforcing measurable sustainability goals, these regulations push companies toward cleaner technologies that align with the circular economy.

Moreover, public procurement policies often prioritize products made under sustainable conditions. As a result, companies using RepMold gain access to new markets and partnerships. Regulations are not just about compliance—they serve as a catalyst for industry-wide transformation toward green growth.

Improved Quality

A key achievement of the RepMold approach is improved product quality. The integration of advanced technology and digital design ensures precision, consistency, and durability. Products manufactured using this process often meet or exceed industrial standards while reducing material waste.

Manufacturers can run iterative design improvements quickly, testing and refining molds without delaying production. This reduces defects, lowers returns, and enhances overall efficiency. The outcome is fewer wasted resources and better consumer satisfaction.

The method’s ability to deliver customized and high-performance parts while maintaining uniformity gives manufacturers a competitive advantage. It proves that sustainability and superior quality can coexist—something traditional methods often struggled to achieve.

Applications of RepMold

RepMold’s versatility allows it to serve a wide range of industries. In the automotive sector, it’s used to produce interior panels, dashboards, and mechanical components efficiently. Its flexibility supports design variation without expensive retooling.

In medical devices, RepMold enables the creation of precision components such as casings and surgical tools while adhering to strict safety standards. Consumer goods manufacturers use the process for packaging, electronics, and custom-designed products where sustainability and speed are key.

It’s also gaining ground in construction, sports equipment, and industrial prototyping. Startups and large enterprises alike can leverage RepMold to balance performance, cost, and environmental impact—achieving sustainability without compromising innovation.

Cost-Performance & Time-Saving

RepMold delivers a strong balance between cost-performance and time-saving. Traditional tooling often requires months to set up, but RepMold can shorten preparation to just days. Faster production cycles mean products reach the market quicker, improving profitability and responsiveness to consumer trends.

By reducing waste and optimizing material use, RepMold helps companies cut down on unnecessary expenses and achieve leaner operations. The reusability of molds not only saves time but also decreases the need for repeated resource extraction.

This model supports short-run production, rapid prototyping, and agile scaling—ideal for industries that rely on quick innovation. Lower costs, improved efficiency, and reduced carbon footprint make RepMold one of the most practical solutions for modern manufacturing.

Future for RepMold

The future looks promising for RepMold as digital manufacturing, AI, and IoT continue to advance. Smart molds that self-monitor and optimize performance could further increase efficiency and reduce waste. Emerging biodegradable materials and sustainable composites will strengthen its alignment with climate change mitigation goals.

In the era of Industry 5.0, customization and sustainability are key. RepMold fits perfectly into this landscape by combining human creativity with technological intelligence. It enables resource efficiency, shorter production cycles, and improved flexibility, helping industries adapt quickly to shifting consumer needs.

As global regulations tighten and renewable energy adoption grows, RepMold will likely become a standard practice rather than a niche innovation. Early adopters will enjoy not just cost benefits but a long-term strategic advantage in sustainability and brand positioning.

Conclusion

In conclusion, RepMold stands out as a revolutionary step in sustainable manufacturing. It combines eco-friendly materials, recycling, and reusing principles with advanced technology to reshape the way products are designed and produced. By reducing waste, cutting costs, and improving efficiency, it provides a solution that benefits both businesses and the environment.

While challenges such as initial investment and scalability remain, the long-term rewards are undeniable. Companies adopting RepMold now will lead in efficiency, sustainability, and innovation. Supported by evolving regulations and growing consumer demand for responsible products, the RepMold process is set to define the next generation of manufacturing.

The transition to sustainable manufacturing is no longer a distant goal—it’s happening now. With RepMold, industries can create smarter, cleaner, and more efficient production systems that safeguard the planet while driving progress forward.

Frequently Asked Questions (FAQs)

What exactly is RepMold?

It’s a manufacturing system combining replication and molding to produce parts efficiently while reducing waste and supporting sustainability.

How does it help the environment?

By minimizing raw material use, enabling recycling and reusing, and lowering emissions, it reduces the environmental footprint of production.

Can it replace traditional manufacturing?

For many short- and medium-run applications, yes. For extremely high volumes, hybrid approaches may still be preferred.

Which industries use it most?

Automotive, medical, electronics, consumer goods, packaging, and construction industries benefit greatly from its flexibility.

What are its main advantages?

Lower costs, better quality, faster production, waste reduction, and enhanced sustainability.

What are the biggest challenges?

Upfront investment, scaling for high-volume runs, and ensuring consistent quality with eco-friendly materials.

How do regulations support it?

Policies encouraging circular economy, renewable energy use, and low-emission production make RepMold adoption easier and more profitable.

What does the future hold for this technology?

With advances in digital tools, smart molds, and eco-materials, RepMold will become central to global sustainable manufacturing strategies.